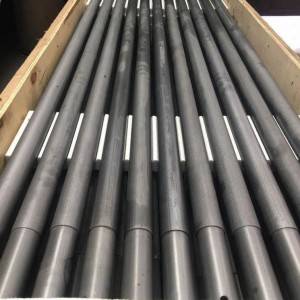

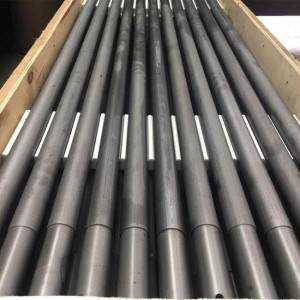

Roller

Product Qaqileng

Itšoara joang Sintered Silicon e Carbide Rollers ba tšoauoa ka babatsehang phahameng mogote kobang matla, ho kena moea ho hanyetsa, bartolomeo qhoaele ho hanyetsa, ho roba mahala ka tšebeliso ea nako e telele ka mocheso phahameng, bending mahala le deformation.

Kopo:

E ka sebelisoa libakeng tse nang le mocheso o phahameng oa li-kilns tsa li-roller bakeng sa letsopa la letsatsi le letsatsi, letsopa la bohloeki, porcelain ea moaho, khalase le lisebelisoa tsa makenete. Bophelo ba ts'ebeletso bo feta makhetlo a fetang a 10 a aluminium oxide ceramic rollers.

Matšoao a Maholo a Tekheniki ea Lihlahisoa tsa Silicon Carbide ea Reaction-sintered

|

Ntho |

Yuniti |

Lintlha |

|

Mocheso o sebetsang |

℃ |

1380 |

|

Ho teteana |

g / cm³ |

.03.02 |

|

Porosity |

% |

< 0.1 |

|

<0.1 |

Matla a kobang |

250(20Mpa |

|

Matla a kobang |

) |

|

|

EA-280 (1200 ℃) |

Elastic Modulus |

330(20Mpa |

|

Elastic Modulus |

Gpa |

|

|

EA-300 (1200 ℃) |

Thermal Conductivity |

W / mk |

|

EA-45 (1200 ℃) |

KThermal Katoloso ea Coefficient-1× 10 |

-6 |

|

4.5 |

13 |

|

|

Boima ba Mohs |

Alkalinity le Acidity |

E khabaneMatla a Kamang a RBSiC (SiSiC) Roller

ke 250MP, polokeho coefficient makhetlo a 5, le bolelele ba ho jara bokgoni ba 1 mitha. Haeba bolelele ba sehlahisoa ke L, matla a ho jara a ka baloa ka foromo e latelang:

Matla a Kamang a RBSiC (SiSiC) Matla a Ts'oenyehileng = Boleng ba Bokaholimo 1 / L, Lebotho le Behang la Matla a Kabo a Tšoanang = Boleng ba Bokaholimo * 1 / L. Mocheso o sebetsang oa matla a ho jara ke 1380 is.

|

Lethathamo la Matla a Jereng Mojaro |

Bolelele (limithara) |

Likarolo tsa likarolo |

Tse tsepamisitsoeng Loading (kg) |

||

|

L |

E tsamaisoa ka mokhoa o sa lekanang Loading kg) |

D1 |

δ |

||

|

1 |

35 |

23 |

6 |

70 |

140 |

|

1 |

40 |

28 |

6 |

97 |

194 |

|

1 |

45 |

33 |

6 |

130 |

260 |

|

1 |

50 |

38 |

6 |

167 |

334 |

|

1 |

55 |

44 |

7 |

261 |

522 |

|

1 |

60 |

46 |

7 |

283 |

566 |

|

1 |

80 |

46 |

8 |

604 |

1208 |

D2

Paka: Ka ditlhoko

Nako ea ho fana: 1 * 20GP setshelo se nka matsatsi a 10-20

MOQ: likarolo tse 5