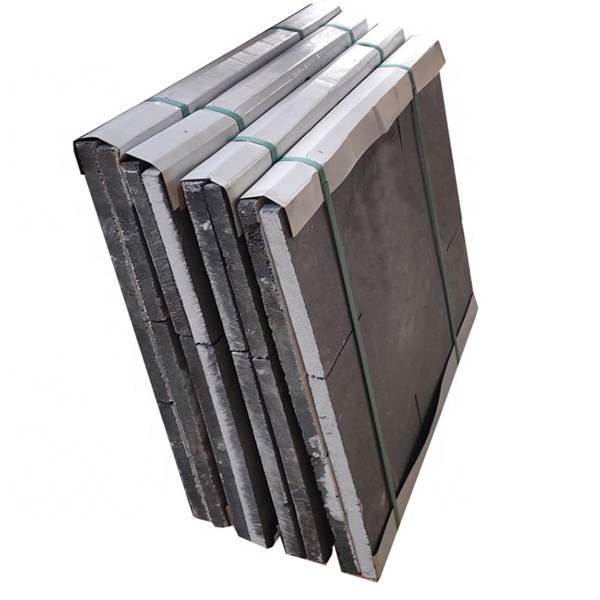

silicon carbide batts

Product qaqileng

Sekhahla se phahameng, bokaholimo bo boreleli. Mocheso o phahameng le matla a ho patala le ho fetoha ha maemo, ha ho na deformation. Ho tima ho hanyetsa, ho hanyetsa mocheso o motle, ha ho bonolo hakaalo. Khanyetso e ntle ea oxidation, e neng e sebelisoa ho chesa moea oa sebōpi le ho fokotsa sepakapaka. E ka ntlafatsa sekhahla sa ts'ebeliso ea sebōpi le sekhahla sa ho boloka matla.

Ha ho bapisoa le recrystallized le nitride bonded sic, ts'ebetso ea nako e telele ea li-reaction-sintered sic e betere. Matla a feto-fetohang a sic-sintered sic a feta habeli a recrystallized sic mme e ka ba 50% e phahametse ea nitride bonded sic.

Product ga tlhaloso

Ho latela kopo ea boholo ba moreki kapa ho taka

Kamehla teba (limilimithara):

600 * 500 600 * 470 600 * 400 500 * 500 500 * 370 500 * 340 500 * 450 485 * 460 450 * 450 450 * 420 420 * 380 360 * 360 340 * 340 330 * 330 320 * 320 310 * 310mm

Hlokomela: botenya ka tlhokahalo moreki

Litšobotsi

• baballa matla haholo.

• Boima bo bobebe le matla a phahameng a ho jara.

• Khanyetso e ntle ea khopama mocheso o phahameng.

• Ho khanna ho phahameng ha mocheso

• Moduli oa High Young

• Coefficient e tlaase ea mocheso oa mocheso

• Thatafala haholo

• Matla a phahameng

• Apara e loantšang

• Khanyetso e ntle ea oxidation

Lintlha tsa tekheniki

| Tekanyetso ea Tekheniki | Yuniti | SiC | SSiC | Tlhahiso ea Sic + C. |

| Thatafala | HS | 110 | 115 | 105 |

| Sekhahla sa Porosity | % | <0.3 | <0.2 | <0.5 |

| Ho teteana | g / cm3 | 3,00 ~ 3,05 | > 3.10 | 2.69-2.90 |

| Compressive Matla | MPA | > 2200 | > 2500 | > 1400 |

| Matla a Fractural | MPA | > 350 | > 380 | > 150 |

| Coefficient ea Katoloso ea Mocheso | 10-6 / oC | 4.0 | 4.2 | 3.5 |

| Litaba tsa Sic | % | 90 | 98 | 85 |

| Mahala Si | % | 10 | ≤1 | ≤12 |

| Elastic Modulus | GPa | 400 | 410 | 350 |

| Mocheso | OC | 1300 | 1400 | 1300 |

Hobaneng Khetha rona?

Re na le boiphihlelo bo fetang lilemo tse 10, lisebelisoa tse tsoetseng pele le sehlopha sa litsebi tšimong ena. Ka matla a etellang pele a tekheniki, ts'ebetso e ntle ea ts'ebetso le ts'ebeletso ea boleng, re tsejoa ke bareki indastering ea lik'hemik'hale, peterole, motlakase, metallurgy, thepa ea moaho, sepakapaka, mechini le liindasteri tse ling.